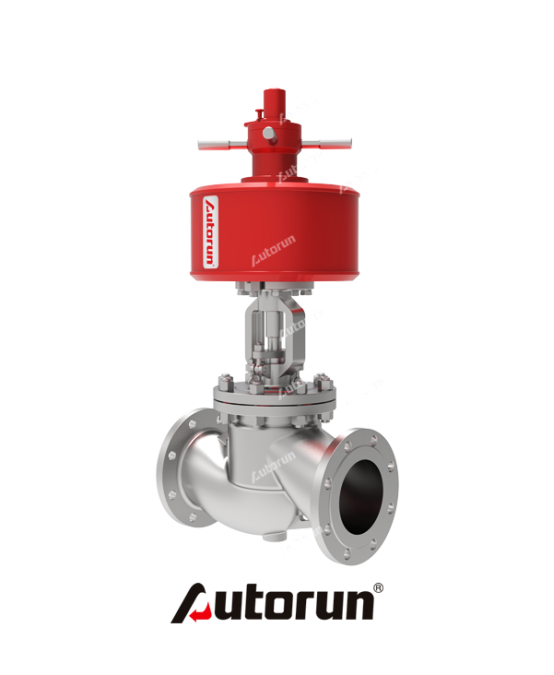

Double-acting Pneumatic Globe Valve with Linear Motion

Consultation and quotationPRODUCT OVERVIEW

Structural composition

Stop valve body

It is a channel for fluid flow, and the valve cavity inside is used to accommodate components such as the valve disc. Common valve body materials include cast steel and stainless steel, etc. They can be selected according to different working medium conditions and pressure and temperature requirements to ensure the strength and corrosion resistance of the valve.

The connection method with pipes is usually flange connection, which is convenient for installation and disassembly.

Pneumatic Actuator (Linear Motion)

It mainly includes components such as the cylinder, piston, and piston rod. The cylinder provides space for the movement of the piston. Under the action of compressed air, the piston moves linearly within the cylinder and transmits the power through the piston rod to the valve stem, driving the valve disc to perform the opening and closing operations of the valve.

Generally, double-acting cylinders are used. That is, by changing the direction of the compressed air entering the cylinder, the up and down movement of the piston is achieved, thereby controlling the opening and closing of the valve.

Other attachments

Electromagnetic valve

It is used to control the entry and exit of compressed air, achieving the action control of pneumatic actuators. According to the control requirements of the valve, different types of electromagnetic valves such as two-position five-way electromagnetic valves (for double-acting pneumatic actuators) can be selected.

Air source trio

It consists of a filter, a pressure reducing valve and an oil mist lubricator. The filter is used to remove impurities and moisture from the compressed air to ensure the cleanliness of the air entering the pneumatic actuator; the pressure reducing valve is used to adjust the pressure of the compressed air to meet the working pressure requirements of the pneumatic actuator; the oil mist lubricator provides lubrication for the pneumatic actuator to reduce the wear of components.

Limit switch

It is used to feedback the on-off position signal of the valve, so that the operator can understand the status of the valve in real time at the remote control center.

Working Principle

When compressed air enters the upper chamber air inlet of the pneumatic actuator, it pushes the piston to move downward. The piston rod then moves downward as well. Through its connection with the valve stem, it drives the valve disc to move downward, opening the valve and allowing the fluid to flow through.When compressed air enters the lower chamber air inlet of the pneumatic actuator, it pushes the piston to move upward. The piston rod moves upward as well, which in turn drives the valve disc to move upward, closing the valve and preventing the fluid from passing through.

Features

Fast response

The pneumatic drive mode enables the valve to open and close quickly, meeting the requirements for rapid response in fluid control. It is particularly suitable for applications where rapid adjustment of flow rate changes is needed.

Reliable sealing

The sealing surface between the valve disc and the valve seat usually adopts conical surface sealing or flat surface sealing, which has good sealing performance and can effectively prevent fluid leakage, ensuring the sealing and safety of the system.

High degree of automation

It can be connected to various automatic control systems to achieve remote control and automatic operation, reducing manual intervention and improving production efficiency and operational accuracy.

Wide application range

It is suitable for various fluid media, including gases, liquids and steam, etc., and can operate under different pressure and temperature conditions, featuring strong versatility.

High output force: Double-acting cylinders have greater thrust compared to single-acting cylinders of the same diameter, capable of overcoming greater resistance. They are suitable for high-pressure differential and large-diameter pipeline systems.

Application Fields

Petroleum and chemical industryIn the power industry

In the metallurgical industry

Water treatment industry

Food and beverage industry: Applicable to the hygienic fluid control in the production process of food and beverages, ensuring the quality and safety of the products.?

Contact Us

Your Name

Telephone

Company

Address

Message