Aluminum Alloy Scotch Yoke Type Pneumatic Actuator

StandardOur company's products are now widely used in various fields such as petrochemicals, natural gas, steel and metallurgy, air separation, mechanical equipment, water plants, pharmaceuticals, etc. They perform particularly outstandingly in working conditions with rapid and frequent switching and harsh pipeline environments.

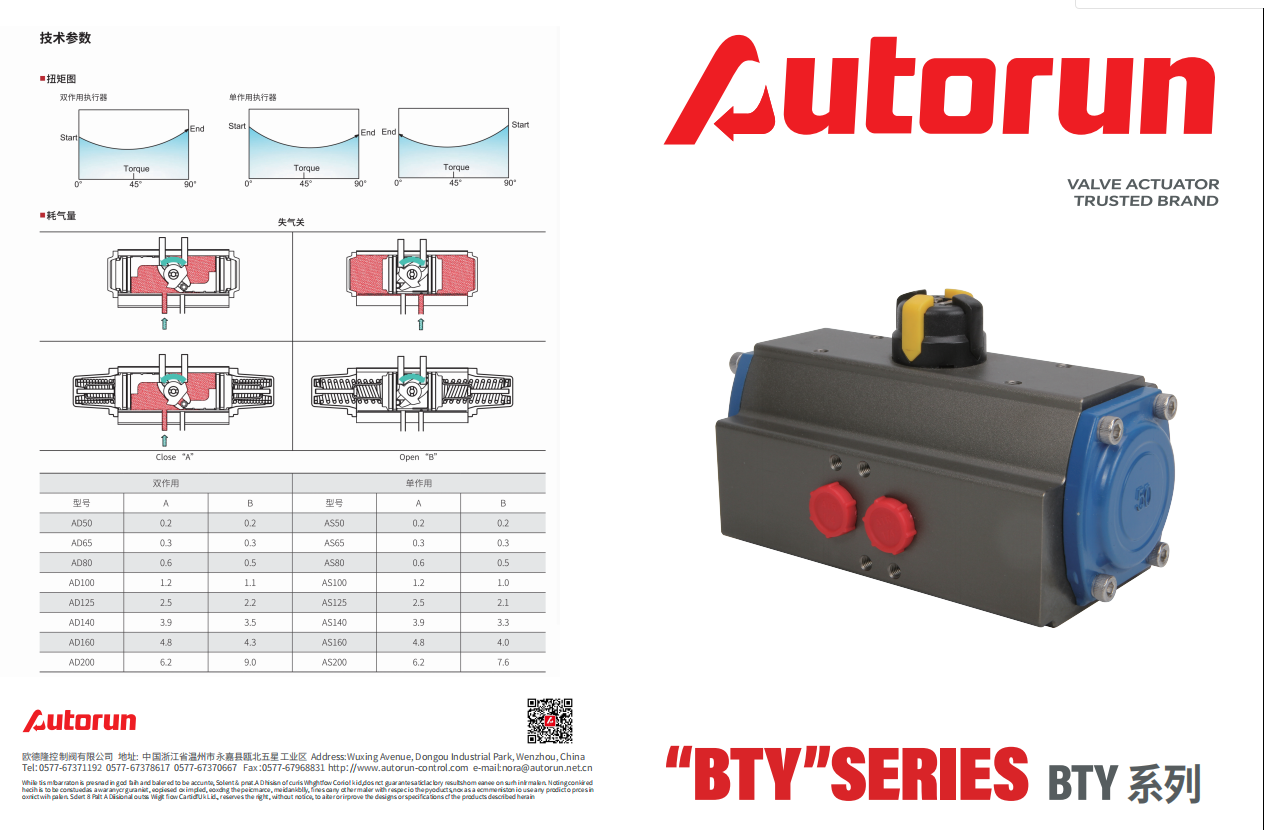

PRODUCT PARAMETERS

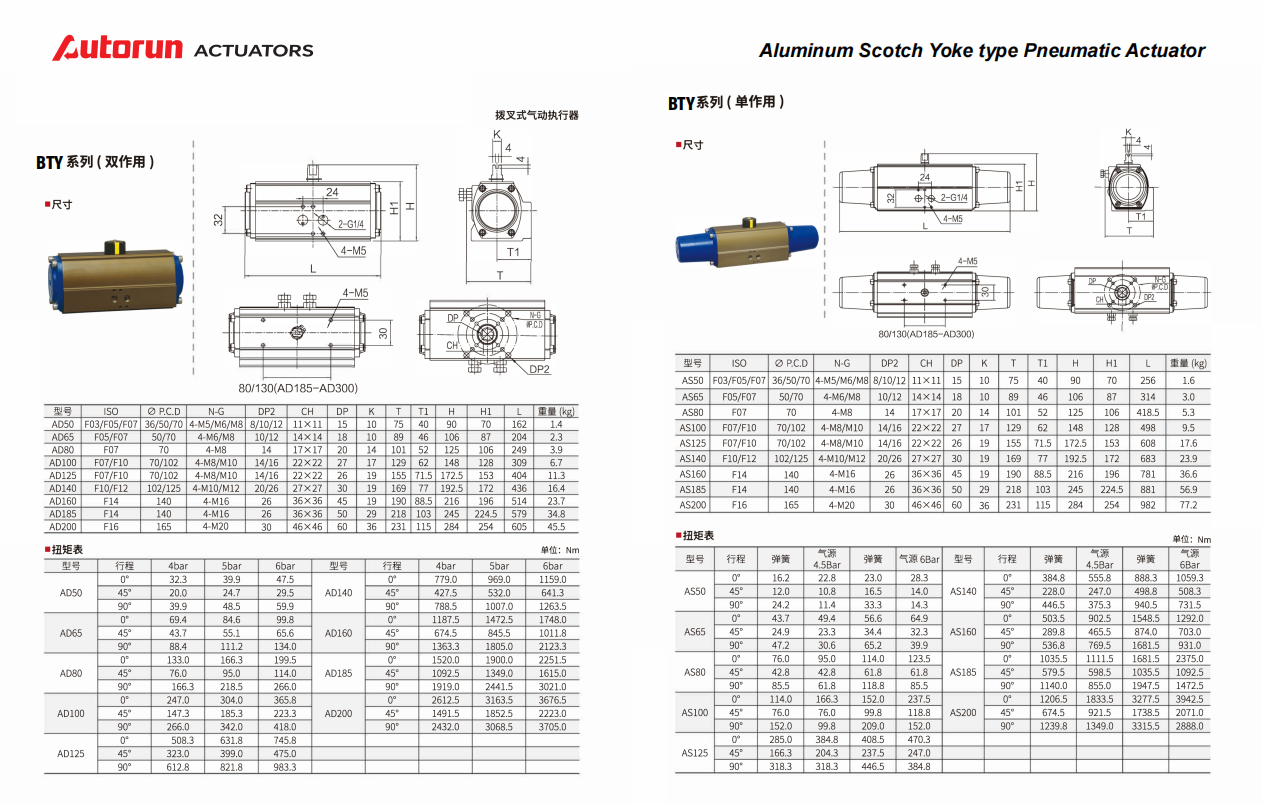

Standard: UNI EN 15714-3:2009

Flange connection standard: UNI EN ISO 5211

Auxiliary equipment connection: NAMUR connection

Rotation angle: 90°

Torque: Directly proportional to the control air pressure

Additional protective housing with hard anodized finish, end cap with epoxy resin coating; marine or other paint available upon customer request.

PRODUCT FEATURES

1. Modular spring pack: Different spring combinations are configured according to different air source pressures. The low-stress spring design can effectively extend the service life of the spring.

2. Corrosion-resistant connectors: All connecting bolts are made of stainless steel and have good corrosion resistance.

3. Piston guide ring: The piston guide ring is made of ultra-high molecular polymer, which has an extremely low friction coefficient. Meanwhile, this material has high hardness, excellent wear resistance, provides precise guidance and a long service life.

4. Housing: The inside of the housing is precisely machined and anodized. The oxide layer thickness is > 20 μm, featuring a low friction coefficient, excellent corrosion resistance and wear resistance.

5. Shaft guide sleeve: It prevents direct contact between the shaft and the cylinder body, ensures the positioning accuracy of the drive shaft, reduces friction loss, and enables the actuator to operate smoothly.

6. Piston guide sleeve: It ensures the positioning accuracy of the piston, enables the piston to run smoothly and continuously, and prevents piston creep.

7. Pin connection: The fork and the drive shaft are connected by pins to ensure synchronous operation of the fork and the drive shaft. At the same time, the pin also plays a role in preventing the drive shaft from flying out, which is a reliable and safe design.?

TECHNICAL PARAMETERS?

| Working conditions | parameter |

|---|---|

Standard | -20℃~+80℃ |

High temperature | -20℃~+150℃ |

Low temperature | -50℃~+60℃ |

Operating pressure | 2-8bar |

Working medium | Dry or lubricated filtered compressed air that complies with ISO 8573-1:2010, Class 3, with a dew point temperature 10 ℃ below ambient temperature. The particulate matter in compressed air meets the requirements of ISO 8573-1:2010, Class 5, with a particle diameter not exceeding 40 μ m. |

Contact Us

Your Name

Telephone

Company

Address

Message